When it comes to aerospace engineering, there is always room for improvement, and a pair of Kennesaw State University mechanical engineering students are starting small.

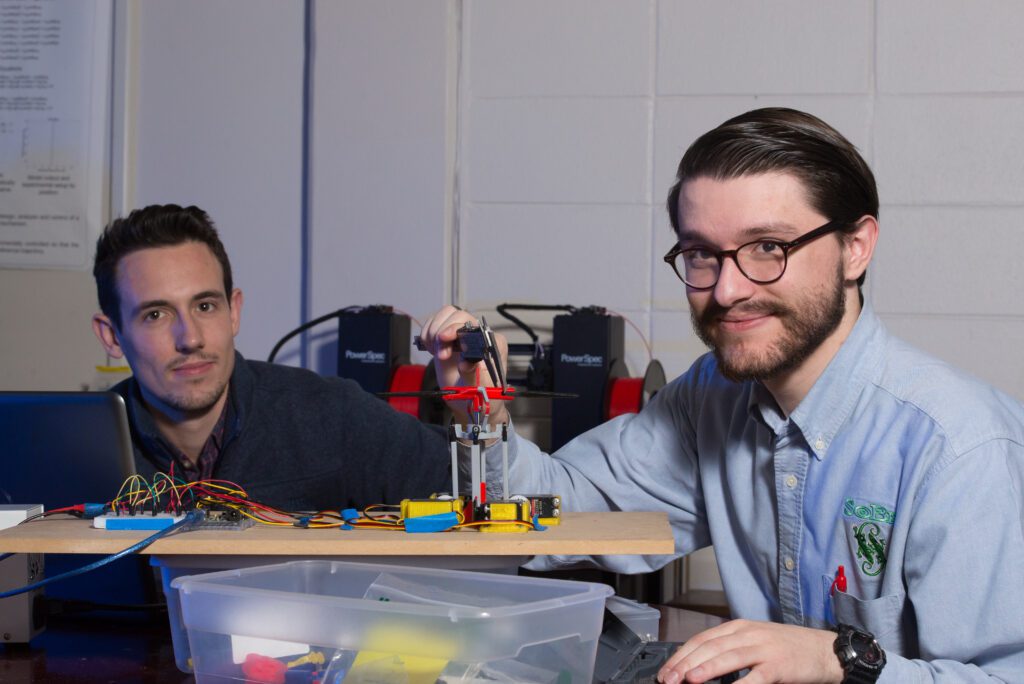

Using a remote-controlled helicopter as inspiration, Niko Giannakakos and Trevor Warnix are developing a more efficient helicopter swashplate, the device responsible for translating input from the pilot into the motion of the main rotor blades. Using a 3D printer, the students have created a jointless swashplate that requires less maintenance and increases output compared to the standard design. The team is now conducting rigorous testing as part of their ongoing research and will present their findings at the National Conference on Undergraduate Research hosted by KSU on April 11-13.

“The unique thing about a model helicopter is, it’s almost exactly the same as a full-blown helicopter only on a smaller scale,” Giannakakos said. “All the same engineering principles apply, though you lose some accuracy. This gives us a great baseline for comparison’s sake.”

Giannakakos, who is interested in pursuing an advanced degree in aerospace engineering upon graduation, said he and Warnix began pursuing the project with the help of two professors in Kennesaw State University’s Southern Polytechnic College of Engineering and Engineering Technology, assistant professor of systems engineering Adeel Khalid and assistant professor of mechanical engineering Ayse Tekes.

Under Khalid, who teaches helicopter theory, Giannakakos learned that one of the focal points of helicopter design is finding a balance in maneuverability and stability, both relying heavily on the swashplate mechanism. Current swashplate designs, however, involve several mechanical links and frequent maintenance. Seeking to simplify and improve the overall output of a swashplate, Giannakakos and Warnix used 3D-printing technology to create a device that uses plastic, flexible links which require no lubrication. The device was modeled using a computer-aided design platform and built with guidance from Tekes, who specializes in compliant mechanisms, a section of mechanical engineering centered around the use of elastic joints.

“This was a really great way to bring together two professors who have very different yet complementary research interests,” Giannakakos said. “Both were constantly pushing us to seek out new information and continually improve on our design, which we have proven is mathematically feasible.”

Though the pair haven’t yet tested their design on a remote-controlled helicopter, they have a developed a working prototype of the compliant swashplate for testing. Warnix said they are using laser displacement sensors and calipers to measure how much output the new design can generate. The team hopes the final design will produce an output at least two times greater than current swashplates.

At NCUR, Warnix said he hopes to interact with students and faculty who have similar interests and to receive critiques on their prototype.

“Being allowed to present at NCUR proves we have a novel idea and is something that warrants more research,” said Warnix, who chose to attend KSU because he sought opportunities to apply his engineering studies through hands-on projects. “I hope to network a lot more and meet other individuals in my field, but I’m also there to learn and see if I can discover other areas that can be researched.”

The Southern Polytechnic College of Engineering and Engineering Technology at Kennesaw State University offers students hands-on learning experiences and produces Georgia’s next generation of work-ready engineers. It is the second largest engineering college in Georgia, serving more than 4,000 students and offering 20 undergraduate and graduate degrees in engineering and engineering technology led by industry-expert faculty in the University’s state-of-the-art facilities.